Fujikura FSM-60S universal fiber optic fusion splicer

Product code: 1000827

Add item to cart. Our specialist will coordinate with you the complete set, tell you the price and delivery time.

Price on request

Out of production. Recommended replacement: Fujikura 86S+

SHORT DESCRIPTION

Fujikura FSM-60S is a Japanese fiber optic fusion splicer, unpretentious and very reliable. Splices any type of fiber with minimal loss. Service life, even in the most severe conditions, exceeds 10 years. Authorized service in Kyiv with the replacement of the device for the period of repair.

Main characteristics:

Alignment to the core of an optical fiber.

Average splicing losses: 0.02 dB (single mode), 0.01 dB (multimode).

Splicing time (auto): 10 s. Heat shrink time: 30 s. Arc power autotuning.

Number of welding/heat shrink cycles per battery charge: 160.

Operating temperature range: from -10°С to +50°С. Weight: 2.7 kg.

High protection against dust, moisture, shock and drops.

Winner of competition: "Best Innovative Product/Solution" at EEBC 2011 and expoTel 2011

Out of production. Recommended replacement: Fujikura 86S+.

The standard warranty for Fujikura fiber splicers is 3 years. When buying a set of equipment (for example fusion splicer + reflectometer) discounted. We also provide professional training with the issuance of a personal certificate. All details can be found by phone: (044) 338-11-77, (097) 650-11-77, (095) 650-11-77, (093) 650-11-77.

DETAILED DESCRIPTION

The quality and excellent performance of the Fujikura FSM-60S fusion splicer were awarded the award of the competition "Best Innovative Product/Solution", which was held as part of the EEBC 2011 and expoTel 2011 exhibitions.

Fujikura introduced the latest FSM-60S welding machine, the next generation of the popular machine FSM-50S, setting new standards in the class of automatic welding machines in terms of environmental protection, speed, size and weight.

The new model of the Fujikura FSM60S welding machine differs from the previous model 50S in reduced dimensions and dust-moisture-shock resistance. In addition, thanks to auto-tuning of the arc power, it is now possible to make more than 1000 welds on one pair of electrodes as on FSM-50S, a 2500 splices, and on one battery charge you can perform about 160 heat shrink welds. The device has lost some weight, with the battery its weight is 2.7 kg. In the new series of devices (FSM-18S and FSM-60S) for ease of installation, a special screw-on table is supplied with the case.

The Fujikura FSM60S splicer is designed for splicing all types of optical fibers c fiber core alignment. Typical splicing time for single mode (SM) fibers in AUTO mode is 10 Seconds. Built-in thermal oven 30 modes provides a typical heat shrink time for Fujikura sleeves equal to 30 seconds. The device is designed to work in the most severe operating conditions. FSM-60S has high protection against dust and moisture, is not afraid of bumps and falls, provides operation in the temperature range from -10°С to +50°С.

The fast response time of the FSM-60S makes it unnecessary to use an additional KDZS heat shrink oven, which is used in older welding machines. At the same time, for special work in laboratory and production conditions, it is provided to connect a second furnace or a thermal stripper to the welding machine.

Welding machine FSM-60S Russified and comes with a user manual in Russian. Great for all types of networks, including backbones.

PAS - Reliable Core Alignment Technology

PAS (Profile Alignment System) is a technology developed by Fujikura to ensure precise convergence of optical fibers along the core with simultaneous alignment in two planes: X and Y. With PAS core convergence technology, the Fujikura FSM-60S splicer can compensate for the influence of various factors, negatively affecting the quality of the welded joint: manufacturing inaccuracy in the location of the fiber core in relation to the sheath, small bends at the ends of the fiber at the welding site, contamination of the V-shaped grooves of the apparatus or the fiber itself. At the same time, 6 high-precision micromotors are used to move the fibers.

In addition, thanks to the analysis of the light profile of the fiber, the Fujikura FSM-60S splicer automatically determines the types of spliced fibers: single-mode SM (ITU-T G.652), multi-mode MM (ITU-T G.651), as well as: DS (ITU-T G.651). T G.653), NZDS (ITU-T G.655), ITU-T G.657, etc.

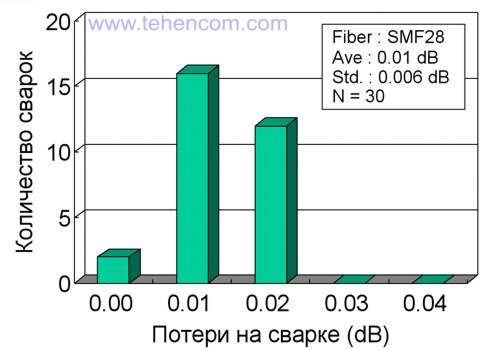

Typical loss Fujikura FSM-60S with 30 test splices on single mode fiber

Thanks to the advanced core convergence technology that automatically optimizes the welding parameters, the FSM-60S consistently delivers a high quality weld, even in the presence of various negative factors. The losses from 30 test splices on single mode (SM) fiber are shown below.

Arc power auto-tuning

The Fujikura FSM-60S welding machine uses automatic arc power adjustment. The machine analyzes the light intensity of the fiber cladding during the previous splicing and, based on this, adjusts the arc power for the next splice. This operation is automatically performed every time you weld. This makes it possible to automatically compensate for electrode wear, as well as the effects of pressure, humidity and temperature. For the user of the machine, auto-tuning of the arc power provides the following advantages:

- extended electrode life: 2500 splices (in the previous model FSM-50S there were 1000 welds);

- increase in work efficiency: there is no need to frequently manually perform arc calibration;

- increase in welding quality: automatic adjustment of the arc power reduces welding losses;

- increased reliability: the device does not have pressure, humidity and temperature sensors.

Extended Battery BTR-08

The Fujikura FSM-60S welding machine adopts the new BTR-08 high-capacity Ni-MH battery and various energy-saving technologies. The FSM-60S, with a fully charged battery, typically delivers 160 heat shrink seal cycles. Unlike Li-ION batteries, the BTR-08 battery provides longer operation at low temperatures down to -10°C.

Software included with each FSM-60S

Each Fujikura FSM-60S welding machine contains a USB connector and comes with a software disk that allows you to:

- remotely control the operation of the welding machine;

- save images during the welding process;

- rewrite from the memory of the welding machine and save in various formats detailed data on the welding work performed;

- in the event of an emergency situation when welding fibers, you can save a detailed report on all parameters of the device, including a screen shot, by pressing one button on the device. This report can be sent as a file to service support (info@tehencom.com) to obtain prompt advice from a specialist;

- independently update the firmware of the device via the Internet. New firmware is released by Fujikura regularly (about once a month) and contains various optimizations of the device, for example, for optimal operation with new types of fiber optic cable. This operation takes 3-4 minutes.

Compactness and light weight of the Fujikura FSM-60S welding machine

For comfortable work, the dimensions of the device and its weight are very important. The overall dimensions of the Fujikura FSM-60S are only 136 x 161 x 143 mm. The weight of the device with a power supply unit from a 220 V network is 2.3 kg, and with a battery only 2.7 kg. The Fujikura FSM-60S welding machine is the lightest and most compact in its class.

Convenient mounting table on the case of the FSM-60S welding machine

For the convenience of work during installation, the standard delivery of each FSM-60S fujikura machine has a special mounting table, on which the welding machine is fixed during operation and auxiliary accessories are located: cleaver, stripper, KDZS, etc. During transportation, the table simply snaps into place on the top of the case .

Increased reliability and protection from dust, moisture, vibration, shock and low temperatures

When developing the FSM-60S welding machine, a Japanese company Fujikura paid much attention to the reliability and durability of the device during long-term operation in harsh conditions. After exposure to dust, moisture, vibrations, shocks and low temperatures, the FSM-60S maintains its high fiber splicing performance (see "Technical Specifications" section below).

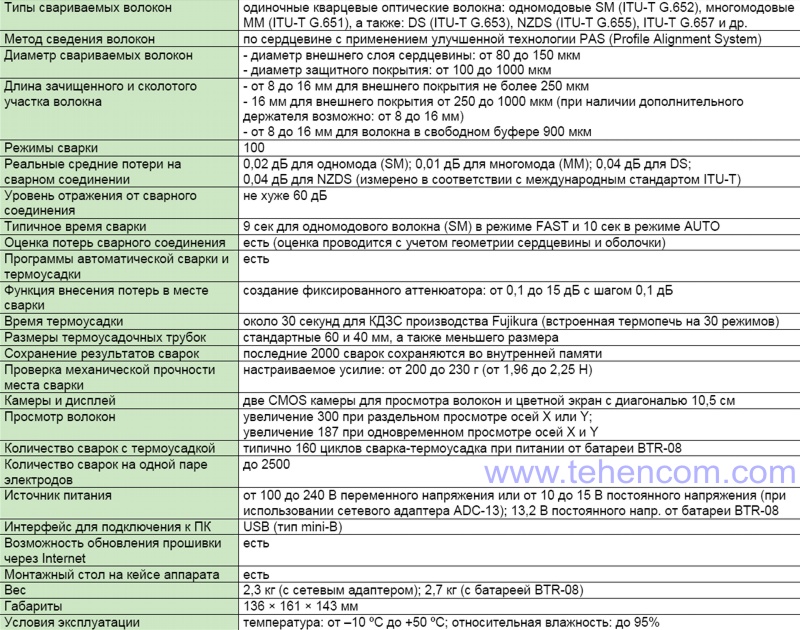

Specifications of Fujikura FSM-60S

Three options for the delivery of the Fujikura FSM-60S fusion splicer

FSM-60S Kit-A Plus (the most complete set):

- Fujikura FSM-60S fusion splicer

- automatic cleaver CT-30A

- accumulator battery

BTR-08

- battery charging cord DCC-14

- power cord for connecting to an external battery (with alligator clips) DCC-13

- hard case CC-24-60S

- mains/charger adapter ADC-13

- power cord ACC-15

- spare electrodes (2 pairs) ELCT2-20A

- receiving tray for JP-05 heat-shrinkable sleeves

- USB cable USB-01

- CD with FSM Data Connection software and training video files

- quick information guide

- detailed printed instruction manual in Russian (120 pages)

- 2 years full factory warranty with the replacement of the device during the repair

FSM-60S "Kit-A" Standard (simpler cleaver):

- Fujikura FSM-60S fusion splicer

- automatic cleaver CT-05A

- accumulator battery BTR-08

- battery charging cord DCC-14

- hard case CC-24-60S

- mains/charger adapter ADC-13

- power cord ACC-15

- spare electrodes (1 pair) ELCT2-20A

- receiving tray for JP-05 heat-shrinkable sleeves

- USB cable USB-01

- CD with FSM Data Connection software and training video files

- quick information guide

- detailed printed instruction manual in Russian (120 pages)

- 2 years full factory warranty with the replacement of the device during the repair

FSM-60S Standard kit (without cleaver):

- Fujikura FSM-60S fusion splicer

- rechargeable battery BTR-08

- battery charging cord DCC-14

- hard case CC-24-60S

- mains/charger adapter ADC-13

- power cord ACC-15

- spare electrodes (1 pair) ELCT2-20A

- receiving tray for JP-05 heat-shrinkable sleeves

- USB cable USB-01

- CD with FSM Data Connection software and training video files

- quick information guide

- detailed printed instruction manual in Russian (120 pages)

- 2 years full factory warranty with the replacement of the device during the repair

Options and accessories

Documentation

Technical description Fujikura FSM-60S (in Russian) (2 pages; 262 KB)

Technical description Fujikura FSM-60S (in English) (2 pages; 297 KB)