Fujikura 86S+ series of fiber optic fusion splicers

Brief description of the series

The Fujikura 86S+ series of fusion splicers contains all the functionality of the previous modification of the Fujikura 86S, plus additional technology for improving the quality of splicing of fibers with large cleavage angles. This technology analyzes cleavage angles in real time and optimizes splicing parameters. Fujikura 86S+ series devices can splice all types of fibers at low temperatures, extreme heat, humidity and wind with minimal losses. At the same time, the splicers are unpretentious and very reliable. The service life even in the harshest conditions exceeds 10 years.

The Fujikura 86S+ series includes three models that differ in cleaver and target region. The Fujikura 86S+ Plus model (set) comes with an automatic Bluetooth cleaver CT50 and additional accessories. The Fujikura 86S+ Standard model (set) comes with a classic cleaver CT16. The Fujikura 90S+ model is designed for the American region and is not sold or serviced in Ukraine. For detailed differences between the models in the series, see the interactive table. A full description of all characteristics can be downloaded below on this page in the Documentation section.

All models of the series

The Fujikura 86S+ series consists of three models, shown in this interactive table. To see all the characteristics of certain models, add them to the comparison.

| Model |

Splice loss SM

|

Splice loss MM

|

Splice time

|

Heat shrink time

|

Battery life

|

Electrode life

|

Cleaver included

|

|---|---|---|---|---|---|---|---|

|

Top sales

Expert's choice

|

0.02 dB | 0.01 dB | 7 sec | 9 sec | 300 splices | 5 000 splices | Fujikura CT50 |

| 0.02 dB | 0.01 dB | 7 sec | 9 sec | 300 splices | 5 000 splices | Fujikura CT16 | |

|

Recommended replacement:

Fujikura 86S+ Plus

|

0.02 dB | 0.01 dB | 7 sec | 9 sec | 300 splices | 5 000 splices | Without a cleaver |

High precision fiber alignment

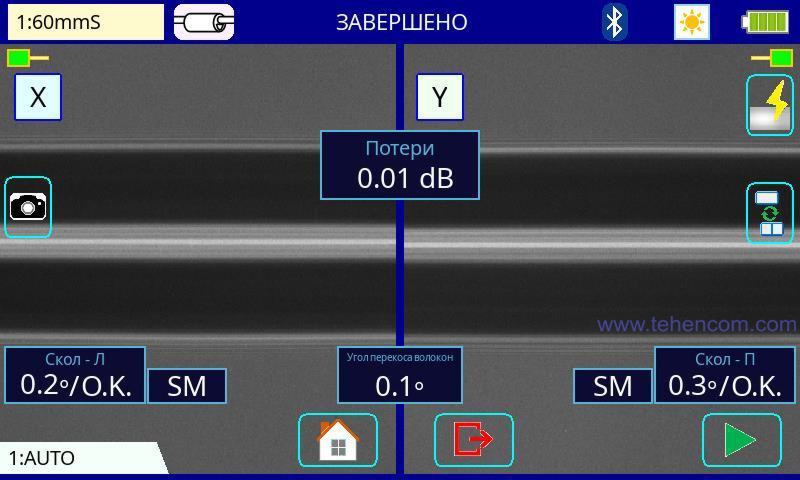

Fujikura's top-of-the-line splicers always provide the best splicing quality. The 86S+ series' optical fiber recognition and alignment system is based on PAS technology. It enables a detailed image of the fiber's central part structure to be obtained, which is necessary for precise alignment along their core, as well as for determining fiber types (SM, MM, G.657, etc.). This screenshot clearly shows the high quality of this image.

The Fujikura 86S+ series fusion splicers use high-quality lenses and optical system sensors, high-precision motors and intelligent software that regulates the alignment and splicing process. This takes into account the type and condition of the fibers, cleavage angles, electrode wear, ambient temperature, humidity, pressure and a number of other important parameters.

Wireless connection with cleaver

Using Bluetooth, one or two Fujikura CT50 automatic cleavers can be connected to the Fujikura 86S+ series splicers. After the first pairing of the splicer and the cleaver, the devices remember the settings and their connection is automatically restored each time they are turned on. This function allows the splicer to keep statistics on the number of fiber cleavages at each blade position, and also automatically rotate the cleaver blade to the next working position based on the analysis of the cleavage angle and its shape.

This screenshot of the 86S+ splicer screen shows statistics on the number of cleaves performed at each of the sixteen positions and three heights of the CT50 cleaver blade. The current working position of the blade is #16 (height 1), the recommended working position by the device is #1 (height 2). Please note that the standard number of cleaves in each position is 1 250 times, and the actual number performed, taking into account the analysis of the quality of the resulting cleaves, can be either greater than 1 250 or less than this value.

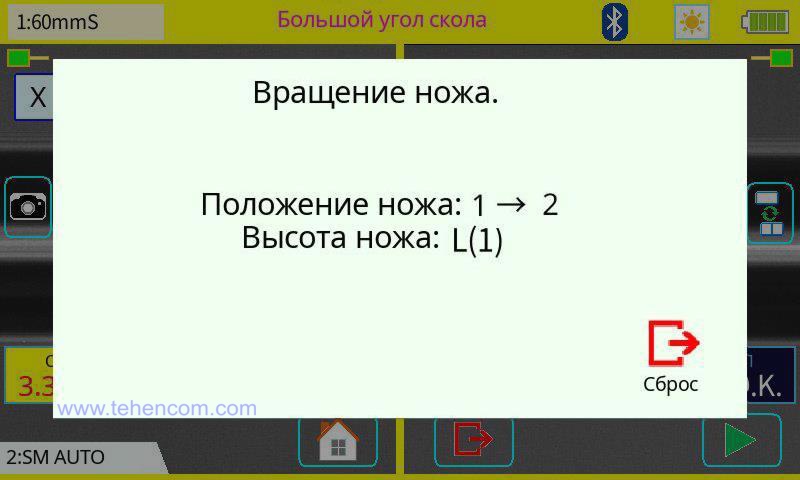

As the blade wears, the cleaving angle and its shape begin to deteriorate. The device continuously analyzes both of these indicators and, when necessary, will automatically turn the cleaver blade to the next working position. In the screenshot below: the regular appearance of a large cleaving angle (3.3 degrees for the left fiber) or an uneven cleaving shape is a sure sign of wear of the current blade position or its contamination.

This is what the information message of the 86S+ series splicer looks like about turning the blade from the first working position to the second. If you want to decide for yourself when to turn the blade, you can switch the automatic rotation to a simple prompt in the splicer settings.

Universal clamps

The Fujikura 86S+ uses fully universal optical fiber clamps that can securely hold fiber in jackets: 0.25 mm, 0.9 mm (regular and loose buffer), 2 mm, 3 mm, Drop Cable and other types. They also increase the speed of work due to the fact that the size and shape of the clamps allow a standard 60 mm wide heat shrink sleeve to be centered on the fiber in one movement.

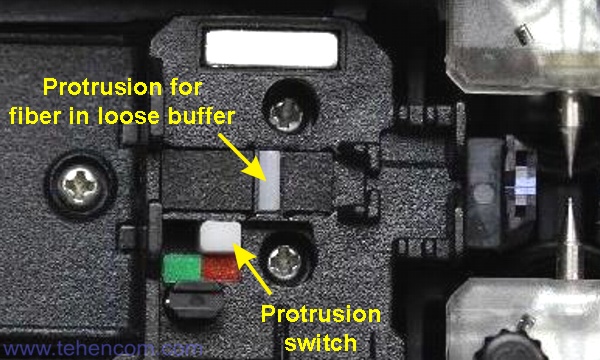

For convenient work with fibers in a loose buffer, a special protrusion was added to the design of the clamps of the splicer, which can be raised and lowered at any time using a switch built into the clamp. Raising the protrusion increases the squeezing force and the fiber in the loose buffer will not slip. For all other types of sheath, raising the protrusion is not required.

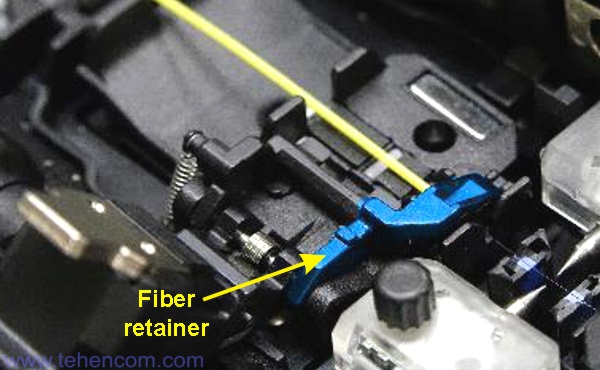

The Fujikura 86S+ clamps have small additional fiber retainers built into the design. Immediately after splicing, when the clamps automatically open, these additional retainers stay in place and gently hold the spliced fiber so that it does not pop out. When you start lifting the fiber to center the heat shrink sleeve, the retainers lift up easily.

You can attach and detach these additional retainers to the corresponding clamp at any time. You can make it so that after opening the clamps only the left or only the right fiber remains fixed, or turn off this function altogether. This photo shows an auxiliary retainer that continues to hold the optical fiber after the left clamp is opened. For clarity, the retainer is highlighted in blue.

Improved case

Traditionally, all Fujikura splicers are supplied in a convenient and reliable yellow transport case. The 86S+ series case is designed in such a way that you can work with the splicer by simply opening the top cover of the case. This ensures normal access to the splicer and there is the possibility of placing the accessories necessary for splicing on the surface of the assembly table. If necessary, you can work by installing the splicer on the lid of a closed case and securing it with a special screw.

Another way to organize your workspace is to use a removable mounting table, which can be removed from the case and placed on any suitable surface. The appearance of the table with the splicer attached to it is shown in this photo.

The mounting table consists of several parts that can be disassembled and assembled in various combinations like a transformer. The left and right parts of the table have sliding transparent drawers in which you can store a cleaver, stripper, spare battery or any other accessories.

Documentation and useful materials

-

Description and characteristics of Fujikura 86S+

RU, 10 pages, 3 MB

-

Instruction manual for Fujikura 86S+

EN, 103 pages, 10 MB

-

Description and characteristics of Fujikura 90S+

EN, 10 pages, 2 MB

-

PC software for Fujikura 86S+, 90S+, 86S, 90S

EN, version 1.0.7.0, 13 MB

-

PC software instruction manual for Fujikura 86S+, 90S+, 86S, 90S

EN, 44 pages, 2 MB