Fujikura CT50 automatic wireless optical fiber cleaver

Product code: 1000242

Add item to cart. Our specialist will coordinate with you the complete set, tell you the price and delivery time.

Price on request

SHORT DESCRIPTION

Fujikura CT50 is a fully automatic cleaver from Fujikura, with built-in Bluetooth wireless interface. The presence of Bluetooth allows the cleaver to communicate with the fiber optic fusion splicer, on the screen of which the current position of the cleaver blade can be displayed. During the operation of the cleaver, its blade gradually wears out, which worsens the quality of the cleave. When the wear of the blade reaches a critical value, the splicer sends a command to the cleaver to rotate the blade via the Bluetooth interface, and the CT50 cleaver itself turns it to the next working position.

An additional advantage of the Fujikura CT50 cleaver is that when the blade is completely used up, the user can replace it himself, since the cleaver design does not require special adjustments after replacing the blade. In addition, the Fujikura CT-50 cleaver is protected from dust, moisture, shock and drops. Its service life exceeds 10 years. Fujikura authorized service is located in Kyiv. You can download a full description of all the characteristics of the Fujikura CT50 automatic cleaver below on this page in the section Documentation.

Main characteristics:

Cleaving of single and ribbon fibers (up to 12 fibers):

- single fiber, cleave length from 5 to 20 mm

- ribbon fiber (from 2 to 12 fibers), cleave length 10 mm (with holders FH)

Blade resource: 60,000 cleaves. Cleave angle error: 0.5 degrees.

Built-in Bluetooth interface for communication with the fiber optic fusion splicer.

Automatic blade rotation as it wears out, or manually using the button on the cleaver. Easy blade replacement. Protected from dust, moisture, shock and drops. Dimensions: 120 x 95 x 58 mm. Weight: 300 g.

One-step cleaving, automatic blade rotation

DETAILED DESCRIPTION

The Fujikura CT50 Automatic Optical Fiber Cleaver cleaves the fiber with a special blade made of CB-08 high-strength steel. Each blade position is rated for 1250 cleaving operations. As the blade wears, it can rotate in a circle and lock into 16 different positions. After the blade has worn out in all sixteen positions, it can be raised twice in height, which makes it possible to use its full cutting circle twice again. Thus, the total resource of the blade is: 1250 * 16 * 3 = 60,000 cleaves. After the resource of the CB-08 blade is exhausted, it can be easily replaced by a new one by the user without sending the cleaver to a service center.

The Fujikura CT50 cleaver is included in the Plus kit of the Fujikura 86S+ and Fujikura 42S fusion splicers.

Operating principle of Fujikura CT50 optical fiber cleaver

The design of the Fujikura CT50 cleaver allows for the fastest possible fiber cleaving. When you open the cleaver cover, you automatically cock the blade, no additional buttons need to be pressed to cock the blade. When the lid is completely lowered, the mechanism for moving the blade is triggered and the fiber is cleaved, and its cut is pulled into the side container by a special roller. When you open the lid again to remove the cleaved fiber, the blade automatically cocks again.

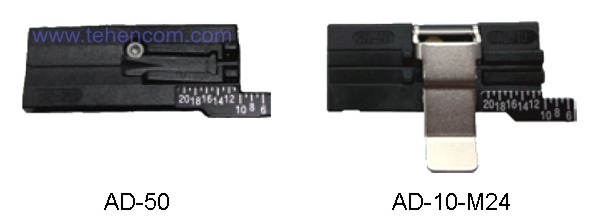

Two types of Fujikura CT50 cleaver pads: AD-50 and AD-10-M24

The Fujikura CT50 Cleaver comes standard with two types of optical fiber mounting pads (AD-50 and AD-10-M24), each of which is optimal for a particular style of work. For high-speed work of an experienced welder, the AD-50 platform is excellent, which does not have a pressure plate, which allows you to very quickly lay the fiber on it, holding it with your hand and transfer it to the machine immediately after the cleavage.

For novice welders, or experienced welders who prefer slower and more accurate work, the fiber installation platform with the classic AD-10-M24 pressure plate is more suitable. Both sites are shown in this photo.

Fujikura CT50 cleaver blade turning and lifting easy procedure

The Fujikura CT50 cleaver uses a new type of CB-08 blade, which features a clear marking of the current position (see photo below). In total, the blade has 16 working positions, each of which is designed for an average of 1,250 cleaves. As the current position of the blade becomes dirty and worn, the quality of the fiber cleavage gradually deteriorates, and when the cleavage angle begins to regularly exceed 1 degree, it is necessary to gently wipe the working edge of the blade with alcohol. If, after cleaning the blade, the cleavage angle still consistently exceeds 1 degree, then it's time to turn the blade to the next working position.

In the Fujikura CT50 cleaver, the blade turning procedure can be performed in three different ways: (1) by pressing the button located on the cleaver, (2) by turning the special wheel located at the bottom of the cleaver body, (3) via Bluetooth interface using a Fujikura fusion splicer or smartphone. Please note that when manually turning the blade using the wheel, the cover of the Fujikura CT50 cleaver must be in closed position.

After the blade CB-08 is worn in all sixteen positions, it can be raise twice in height, which makes it possible to use its full cutting circle twice again. In order to raise the blade to the next working position, you just need to move the special wheel located in the central part of the cleaver (right under the lid lock) one position. The CT50 cleaver is then ready for another 20,000 cleavers.

Built-in Bluetooth cleaver Fujikura CT50

The Fujikura CT50 optical fiber cleaver is equipped with a built-in Bluetooth module, which allows you to exchange data with the fusion splicer Fujikura 42S or Fujikura 86S+. The cleaver sends the device information about the current position of its blade (turn position and height) via a wireless interface, and the device keeps a record of the number of cleaves, analyzes their quality, and when it becomes necessary, sends a command to the cleaver to turn the blade to the next working position. Upon receiving a command, the cleaver will automatically rotate the blade.

This video, using the Fujikura 36S as an example, explains this function in detail. It will be useful for both beginners and experienced welders, as it improves the quality of splicing and saves time.

Drop Test of Fujikura CT50 Cleaver

During operation, any cleaver will sooner or later be dropped onto a hard surface. Due to a strong impact, in most models of cleavers, this leads to deformation and displacement of the mechanism parts and, accordingly, a deterioration in the quality of the cleavage. But the design of the Fujikura CT50 Optical Fiber Cleaver provides increased protection against bumps and drops (as well as against dust and moisture).

This video shows a drop test of a CT50 cleaver followed by cleaving and splicing two fibers. At the moment, only Fujikura cleavers provide such high resistance to drops and bumps.

Specifications of Fujikura CT50 Optical Fiber Cleaver

Fujikura CT50 optical fiber cleaver delivery set

- cleaver of single and ribbon fibers Fujikura CT50

- a platform for installing fibers with a pressure plate AD-10-M24

- installation site SPA-CT08-10 (attached to cleaver)

- miniature hex key HEX-01

- short instruction M-CT50-E

- plastic case for carrying the cleaver CC-37

- warranty: 1 year (it is possible to extend the warranty period up to 3 years)

Optional Accessories for Fujikura CT50 Optical Fiber Cleaver

- plastic wheel BRW-CT08-01 with marking of blade positions

- blade CB-08 for Fujikura CT50 cleaver

Removable holders Fujikura FH-60 series for different types of fiber buffer:

- FH-60-250 (for bare fiber 0.25 mm)

- FH-60-900 (for pigtails with 0.9 mm sheath)

- FH-60-DC250 (for 0.25 mm bare fiber with DropCable jacket)

- FH-FC-20 (for patch cords in 2 mm sheath)

- FH-FC-30 (for patch cords in 3 mm sheath)

- FH-60-LT900 (for pigtails in free buffer 0.9 mm)

Documentation

This PDF documentation contains the most comprehensive description of the Fujikura CT50 Automatic Fiber Optic Cleaver, its specifications and operating modes.

Description of automatic cleaver Fujikura CT50 (in English) (2 pages; 1 MB)

And here you can find our tips and other useful information on this topic:

Types of devices according to the method of alignment (alignment) of optical fibers

Effect of electrode wear on splice quality, electrode replacement procedure

How to buy equipment cheaper - discounts, special prices, demo and used devices

To simplify the process of choosing a fiber optic cleaver, you can use our experience and recommendations. We have over 20 years of practical supply experience and can immediately answer many questions about models, options, delivery times, prices and discounts. This will save your time and money. For this it's simple call us or write to us at Email and we will be happy to answer your questions.