Fujikura 36S compact fusion splicer for fiber optic

Product code: 1000238

Add item to cart. Our specialist will coordinate with you the complete set, tell you the price and delivery time.

Price on request

Out of production. Recommended replacement: Fujikura 42S

SHORT DESCRIPTION

Fujikura 36S is a compact fusion splicer for access networks, PON, FTTx, SCS and local fiber optic communication lines, which the Japanese company Fujikura introduced to replace the previous modification Fujikura 22S. The 36S model has been sold in Ukraine since the end of 2018 and differs from the 22S model in having a touch screen and a built-in Bluetooth module for connecting the device with the CT50 cleaver. In addition, Fujikura 36S more accurately evaluates splice losses by analyzing, in addition to the final image of the weld, also the image of the fibers during the glass cooling process.

For the price and features, the Fujikura 36S is the ideal tool for the construction and maintenance of any city-wide fiber optic network. The Fujikura 36S is very handy and compact (weight 1.3 kg.). The charge of the built-in rechargeable battery is enough for 200 heat shrink weldings. On the 36S, fiber alignment is performed using active (moving) V-grooves, which provides excellent performance: the average splicing loss in real conditions is 0.03 dB for single-mode fiber and 0.01 dB for multi-mode.

Through innovation and many years of experience in the development of welding machines, the new model Fujikura 36S welds any type of fiber (including bend-insensitive G.657) with high accuracy and minimal losses even in harsh conditions (low temperature, extreme heat, humidity, wind), while the welder is reliable and unpretentious in operation. The service life of the Fujikura 36S welding machine, even under the most severe conditions, exceeds 10 years.

Authorized device service located in Kyiv. Owners of the 36S model will be pleased with very cheap consumables: a pair of ELCT2-16B electrodes, designed for 5000 welds, costs only $60 (about 1 cent per weld).

Main characteristics:

Alignment of optical fibers with active (moving) V-grooves.

Average welding losses: 0.03 dB (single mode), 0.01 dB (multimode).

Welding time: 6-9 s. Heat shrink time: 16-25 s. Electrode resource: 5000.

The number of welding / heat shrink cycles from a standard Li-ion battery: 200.

Universal clamps fiber optics: 0.25mm, 0.9mm, 3mm, Drop Cable, etc.

Cleave length: 5mm to 16mm. Ability to weld connectors SC, LC, etc.

Auto-adjustment of arc power. Free firmware update via the Internet.

Operating temperature range: from -10°С to +50°С. Weight with battery: 1.3 kg.

Color touch screen. Cleaver control via Bluetooth.

Russified menu. High protection against dust, moisture, shock and drops.

3 years of a full factory warranty with the replacement of the device for the period of repair.

The ideal tool for any city-wide fiber optic network

In addition, Fujikura releases the most functional model of the core convergence splicer: Fujikura 80S. Model 36S uses a conventional tray type heat shrink oven and the optical focus of the fiber recognition system is fixed on the fiber core, so it has 4 motors to move the fibers. And the 80S model uses a high-speed oven that compresses the sleeve during heat shrinking (a separate motor is involved for this) and there are two additional motors that move the lens of the device and allow it to accurately focus on different parts of the fiber. Due to this, the 80S works faster and provides minimal welding losses, but it is larger and more expensive than the 36S.

Need the most functional device for all types of networks? see model Fujikura 86S+.

Want to see the full list? Go to main page fiber splicers.

Difficult to decide on a model? See article: optical fiber alignment methods.

Video review of Fujikura 36S compact fiber splicer

The representative of Fujikura in the USA, AFL, in this overview video, demonstrated the main advantages of the compact Fujikura 41S welding machine (in Japan and the USA, the 36S model is called 41S).

Among the main advantages of the 36th machine are shown: active fiber alignment technology (Active V-Groove), technology for accurate loss assessment using Warm splice image analysis of the fibers during their cooling after splicing (Warm splice image analysis), a capacious battery that is enough for 200 splices with heat shrink, reliable electrodes with a resource of 5,000 splices and easy replacement, control via Bluetooth radio interface of the position of the CT50 cleaver knife (automated blade rotation).

DETAILED DESCRIPTION OF THE FUJIKURA 36S FIBER WELDING MACHINE

At the end of 2018, the line of devices of the Japanese company Fujikura, presented in Ukraine, was replenished with a new model: Fujikura 36S (in some other countries the same device is called Fujikura 41S). The novelty performs the convergence of fibers with the help of active (moving) V-grooves, thanks to which it is positioned as an ideal welding machine model for access networks, PON / FTTx, SCS and local fiber optic communication lines. For those who plan to work with trunk fiber optic communication lines with a length of more than 20 km, as well as for those who require the highest possible quality of welding in any conditions, we recommend that you opt for the oldest model: Fujikura 80S.

If you are building local (urban area) optical networks, access networks, PON/FTTx (passive optical networks) or SCS (structured cabling systems) and want to take advantage of active fiber convergence, then the new apparatus Fujikura 36S suits you perfectly. It is very convenient and compact (1.3 kg with battery), dust-moisture-shock-resistant, with very cheap electrodes (about 1 cent for welding) and a convenient compact case for transportation. But most importantly, the Fujikura 36S welding machine is guaranteed to weld all types of modern fibers: single-mode SM (G.652/657), multi-mode MM (G.651), DSF (G.653), NZDSF (G.655), with minimum loss in its class: 0.03 dB (single-mode), 0.01 dB (multi-mode). The machine accepts heat shrink sleeves (SHS) from 20 mm to 60 mm and can be used to terminate fibers with Fujikura FuseConnect weldable connectors, as well as to splice noodle type optical cable (Drop Cable).

The built-in battery of the Fujikura 36S is enough for full 200 welds with heat shrink. The machine's memory can store 100 pre-configured welding modes and 30 heat shrink modes, the parameters of which can be changed if necessary.

In Ukraine and the CIS, welding machines of the Japanese company Fujikura have been widely used since 1989 and have proven to be extremely reliable: they work for years, cook any type of fiber in severe weather conditions, not afraid of shaking during transportation and accidental drops, and in a critical situation they can be easily and quickly serviced in authorized service center in Kyiv. Fujikura 36S has high protection against dust and moisture and provides operation in a wide temperature range: from -10°С to +50°С.

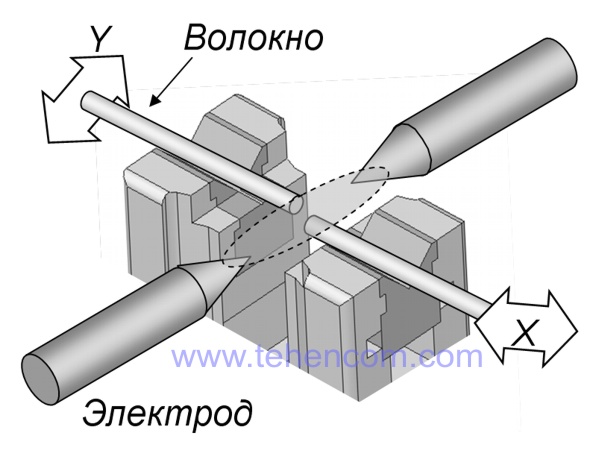

Fiber alignment system with active (moving) V-grooves

The Fujikura 36S uses an active fiber alignment system with moving V-grooves. This convergence system is less sensitive to uneven fiber placement as well as V-groove contamination, as the machine can compensate for mismatched fiber positions caused by dirt particles. In practice, this reduces the requirements for the qualification and accuracy of the welder and slightly increases the quality of the weld. For comparison, the average splicing loss for single-mode fibers with the Model 36S is 0.03 dB, while for machines with fixed V-grooves (models 12S and 19S) loss is 0.05 dB.

Universal clamps (holders) of optical fiber CLAMP-S31A for Fujikura 36S

The Fujikura 36S machine uses CLAMP-S31A universal clamps that allow you to install and splice fibers in various types of buffer coating: bare optical fiber in varnish 0.25 mm, pigtails in a sheath 0.9 mm, patch cords in a sheath 2 and 3 mm, Drop Cable (noodles) and other types. The clips in the 36S are easily removed, for example, if you want to install the removable holders of the series Fujikura FH-60.

For comfortable work with pigtails in a free buffer of 0.9 mm, a special modification of the clamps with increased clamping force is produced: CLAMP-S31B. These additional clamps are included in the maximum package Fujikura 36S "Kit-A" Plus.

The distance from the edge of the CLAMP-S31A to the electrodes of the machine is 30 mm, which makes it very easy to center a 60 mm sleeve before placing it in the shrink oven. This saves valuable welder time. See this video for details.

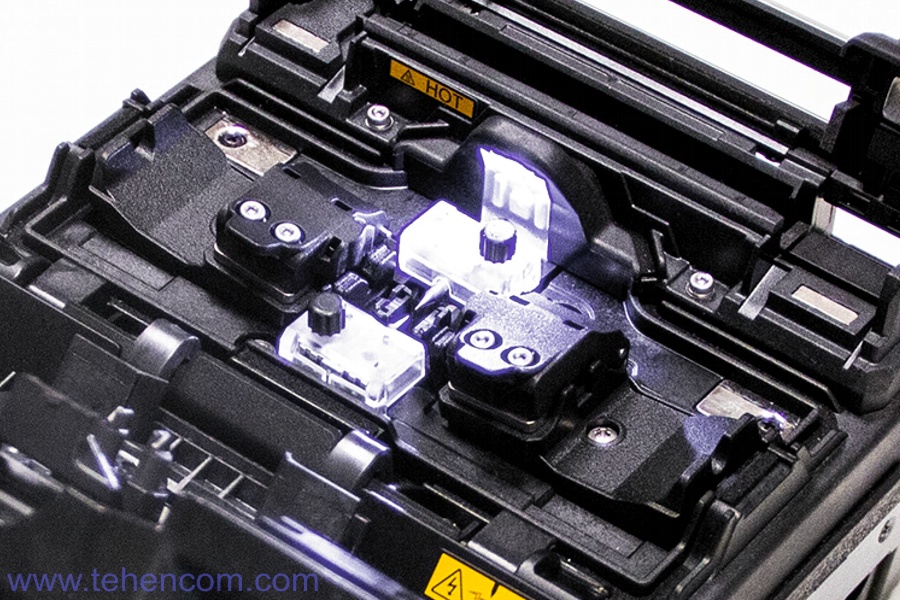

Fujikura 36S' bright LED backlight for comfortable working in dark environments

The Fujikura 36S splicer uses a very bright and voluminous LED backlight, which well illuminates the installation site of the optical fibers. High-quality illumination of the device makes the work of the welder comfortable in places with insufficient lighting and allows you to easily and accurately place the fibers in the device.

Built-in Bluetooth module of Fujikura 36S

The Fujikura 36S welding machine is equipped with a built-in Bluetooth 4.1 module, which allows the machine to control the wear of the cleaver blade Fujikura CT50 and automatically scroll the blade to the next position with a strong deterioration in the quality of the chip. Also, using the Bluetooth interface, the device can control the operation of Fujikura RS02 and Fujikura RS03 thermal strippers.

About the function of automatic detection of wear of the knife of the optical fiber cleaver Fujikura CT50 and its rotation to the next working position is described in detail in this video. In the course of work, the Fujikura 36S welding machine constantly analyzes the quality of all performed chips and, when it becomes necessary, sends a command to the cleaver via the Bluetooth interface to rotate the knife. After receiving the command, the cleaver automatically rotates the knife one position.

This function, which is also built into the machine Fujikura 86S, useful for both beginners and experienced welders, as it improves the quality of welding and saves time.

Low cost of operation Fujikura 36S and cheap consumables

With intensive fiber splicing work, the availability and cost of electrodes is important. The new Fujikura 36S model uses an improved arc power auto-tuning algorithm and now it is possible to make 5000 welds. In this case, ELCT2-16B electrodes are used, which are always in stock. A pair of electrodes costs $60, which in terms of the price of one welding is about 1 cent.

Fujikura 36S is the lightest and most compact welding machine in its class

The Fujikura 36S is the lightest and most compact active V-groove machine in the class. Its dimensions are 131 x 201 x 79 mm with a weight of only 1,300 g including the built-in battery. Despite the compact dimensions of the device, the battery charge is enough for 200 heat shrink welds.

The device itself and accessories are placed in a compact transport case. The transport case provides convenient and environmentally protected transportation of the device, as well as the cleaver and additional accessories.

Inside the case of the Fujikura 36S welding machine there is a modular mounting table on which you can install a welder, an alcohol dispenser and tools: a cleaver, a stripper, napkins, and more. The device is securely attached to the mounting table and cannot fall out of it. The mounting table itself is attached to the welder with a strong strap with two carabiners.

Specifications of Fujikura 36S Compact Fiber Splicer

Three options for the delivery of the Fujikura 36S welding machine

Fujikura 36S Kit-A Plus (the most complete set):

- Fujikura 36S welding machine

- automatic cleaver CT50

- universal fiber holders CLAMP-S31A (installed in the device)

- additional holders for pigtails in a free buffer CLAMP-S31B

- mounting pads SP-31 (1 pair) for installing removable holders of the series Fujikura FH-60

- ELCT2-16B electrodes (1 pair) (installed in the machine)

- Spare ELCT2-16B electrodes (2 pairs)

- BTR-11 rechargeable battery (installed inside the machine)

- ADC-19A AC/Charger adapter

- ACC power cord -11

- alcohol dispenser AP-02

- three position stripper (0.25 mm, 0.9 mm and 2-3 mm) SS03

- USB cable

- quick reference guide

- hard case CC-36

- warranty card for 3 years warranty (2 years factory warranty + 1 year from Tehencom)

Fujikura 36S Kit-A Standard (simpler cleaver):

- Fujikura 36S welding machine

- automatic cleaver CT08 with an additional platform for installing fibers

AD-10-M24

- universal fiber holders CLAMP-S31A (installed in the device)

- mounting pads SP-31 (1 pair) for installing removable holders of the series Fujikura FH-60

- ELCT2-16B electrodes (1 pair) (installed in the machine)

- Spare ELCT2-16B electrodes (1 pair)

- BTR-11 rechargeable battery (installed inside the machine)

- ADC-19A AC/Charger adapter

- ACC power cord -11

- alcohol dispenser AP-02

- three position stripper (0.25 mm, 0.9 mm and 2-3 mm) SS03

- USB cable

- quick reference guide

- hard case CC-36

- warranty card for 3 years warranty (2 years factory warranty + 1 year from Tehencom)

Fujikura 36S Standard Kit (without cleaver):

- Fujikura 36S

fusion splicer - CLAMP-S31A universal optical fiber holders (installed in the machine)

- SP-31 mounting pads (1 pair) for installing removable holders of the series Fujikura FH-60

- ELCT2-16B electrodes (1 pair) (installed in the machine)

- Spare ELCT2-16B electrodes (1 pair)

- BTR-11 rechargeable battery (installed inside the machine)

- ADC-19A AC/Charger adapter

- ACC power cord -11

- alcohol dispenser AP-02

- three position stripper (0.25 mm, 0.9 mm and 2-3 mm) SS03

- USB cable

- quick reference guide

- hard case CC-36

- warranty card for 3 years warranty (2 years factory warranty + 1 year from Tehencom)

Options and accessories for the Fujikura 36S welding machine

Fujikura 36S machines use the CLAMP-S31A universal clamps, which allow you to work with fibers in various types of buffer coating. In addition, the 36S devices are equipped as standard with removable mounting pads SP-31, designed to install holders for various types of fiber optic buffer of the series Fujikura FH-60. In a number of situations, especially for beginners, these holders can be more convenient to use, as they allow you to accurately maintain the cleavage length when transferring the fiber from the cleaver to the device. The appearance of the removable holders of the Fujikura FH-60 series is shown in this photo.

- FH-60-250 (for bare fiber 0.25 mm)

- FH-60-900 (for pigtails with 0.9 mm sheath)

- FH-60-DC250 (for 0.25 mm bare fiber with DropCable jacket)

- FH-FC-20 (for patch cords in 2 mm sheath)

- FH-FC-30 (for patch cords in 3 mm sheath)

- FH-60-LT900 (for pigtails in free buffer 0.9 mm)

Documentation

This PDF documentation contains the most comprehensive description of the Fujikura 36S compact fiber fusion splicer, its specifications and operating modes.

Fujikura 36S Fiber Splicer Description (English) (2 pages; 1 MB)

Fujikura 36S Brief Information Guide (4 pages; 1 MB)

Fujikura Exclusive Distributor Certificate (1 page; 1 MB)

Fujikura Service Center Certificate (1 page; 1 MB)

And here you can find our tips and other useful information on this topic:

Types of devices according to the method of alignment (alignment) of optical fibers

Effect of electrode wear on welding quality, electrode replacement procedure

What is the difference between Fujikura cleavers? Which model to choose? Questions and answers

How to buy equipment cheaper - discounts, special prices, demo and used devices

To simplify the process of choosing a splicer for fiber optics, you can use our experience and recommendations. We have over 20 years of practical supply experience and can immediately answer many questions about models, options, delivery times, prices and discounts. This will save your time and money. For this it's simple call us or write to us at Email and we will be happy to answer your questions.