Fujikura 86S universal fiber optic fusion splicer

Product code: 1000237

Add item to cart. Our specialist will coordinate with you the complete set, tell you the price and delivery time.

Price on request

Out of production. Recommended replacement: Fujikura 86S+

SHORT DESCRIPTION

Fujikura 86S is a top model fiber optic splicer with core alignment, Japanese company Fujikura. Model 86S went on sale in early 2020 and is the continuation of the famous line of welding machines 80S and FSM-60S. Like its predecessors, Fujikura 86S welds all types of fibers with minimal losses in any conditions (low temperature, extreme heat, humidity, wind), while the welder is unpretentious and very reliable in operation. This device has very cheap consumables: a pair of ELCT2-16B electrodes, designed for 5000 welds, costs only $60 (about 1 cent per weld). The service life of the Fujikura 86S, even under the harshest conditions, exceeds 10 years.

In terms of welding quality, the new Fujikura 86S is identical to the previous Fujikura 80S, but it has many improvements to make the welder more efficient and faster. Among the improvements of the 86 machine: universal holders for all types of buffer (including free buffer), battery for 300 splices, wireless connection to two cleavers CT50 with automatic rotation of the cleaver blade, color touch screen and much more.

Main characteristics:

Precise alignment to the optical fiber core (by PAS technology).

Average welding losses: 0.02 dB (single mode), 0.01 dB (multimode).

Welding time: 7-9 s. Heat shrink time: 9-15 s. Electrode resource: 5000.

The number of welding cycles + heat shrink from a standard Li-ion battery: 300.

Universal clamps fiber optics: 0.25mm, 0.9mm, 3mm, Drop Cable, etc.

Cleave length: 5mm to 16mm. Ability to weld connectors SC, LC, etc.

Fully automatic: windproof cover, heater, fiber clamps.

Arc power autotuning. Simultaneous viewing of the welding place along the X and Y axes.

Russified menu. Free firmware update via the Internet.

Color touch screen. Control of two cleavers via Bluetooth.

The highest protection against dust, moisture, shock and drops.

3 years of a full factory warranty with the replacement of the device for the period of repair.

Operating temperature range: from -10°С to +50°С. Weight with battery: 2.8 kg.

Leader in welding/shrink speed, quality and reliability.

Great for all types of networks, including backbones

In addition, Fujikura releases a simpler model of the device with the alignment of optical fibers with active V-grooves: Fujikura 42S. The 42S model has a simpler heat shrink oven and the optical focus of the fiber recognition system is fixed on their core, so the 42S model is structurally simpler (it has 4 motors, not 7 as in 86S+). As a result, the 42S is smaller, lighter and costs half the price of the flagship model 86S+.

Need a welding machine for city-wide networks? see model Fujikura 42S.

Want to see the full list? Go to page optical fiber splicers.

Difficult to decide on a model? See article: optical fiber alignment methods.

DETAILED DESCRIPTION

When developing the Fujikura 86S, a lot of attention was paid to speeding up the entire process of installing optical fibers. For this, the design of the automatic windproof cover was changed, the fiber clamps were completely redesigned, special fiber retainers were added, and the design of the stove was improved. All these improvements have made it possible cut five times opening time of the protective cover and clamps after welding, as well as double speed up centering the sleeve on the welded fiber and installing it in the oven.

In addition to speeding up processes, the designers of Fujikura 86S have worked hard to improve the convenience of work, for this the design of the mounting table and the transport case have been significantly changed. And it is worth noting that up to two automatic cleavers can be connected to the 86S via Bluetooth. Fujikura CT50, thanks to which the machine is able to automatically rotate the cleaver blade to the next working position when necessary. All these features, as well as additional features of the Fujikura 86S model, are described in detail below on this page.

In Ukraine and the CIS, welding machines of the Japanese company Fujikura have been widely used since 1989 and have proven to be extremely reliable: they work for years, cook any type of fiber in severe weather conditions, not afraid of shaking during transportation and accidental drops, and in a critical situation they can be easily and quickly serviced in authorized service center in Kyiv.

Automatic wind cover

For the first time, an automatic wind cover appeared in the previous model. Fujikura 80S and it consisted of two separate parts. In the new 86 model, the protective cover also opens automatically after splicing the fibers, but it consists of one part that opens in the direction opposite to the shrink oven. With this design, nothing prevents the fibers from being transferred from the machine to the heater.

Universal optical fiber clamps

The Fujikura 86S has significantly improved fiber clamps. Now they are completely universal and can securely hold fibers in sheaths: 0.25 mm, 0.9 mm (regular and free buffer), 2 mm, 3 mm, Drop Cable (noodles) and other types. They also increase the speed of the welder, because the size and shape of the new clamps allow a 60 mm wide heat shrink sleeve to be centered on the fiber in one motion.

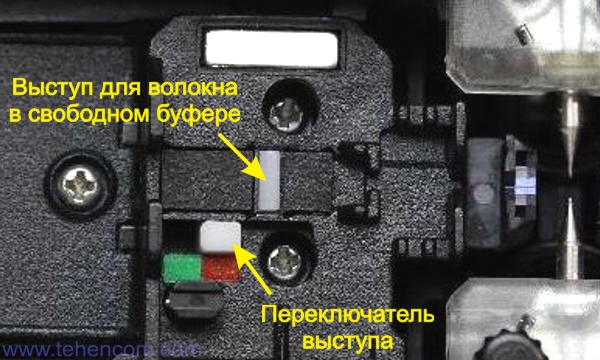

For convenient work with fibers in a free buffer (Loose Tube), a special ledge has been added to the design of the clamps, which can be raised and lowered at any time with one finger movement using the switch built into the clamp. Raising the lug increases the squeezing force and the fiber in the loose buffer will not slip. For all other sheath types, as well as for bare fiber, raising the lug is not required.

The clamps on the Fujikura 86S have small auxiliary fiber retainers built into the clamp design. Immediately after splicing, when the clamps open automatically, these retainers stay in place and gently hold the spliced fiber so that it does not pop out. As you begin to lift the fiber to center the shrink sleeve, the retainers snap off easily.

You can fasten and unfasten these additional fasteners to the corresponding clip at any time. You can make it so that after opening the clamps, only the left or only the right fiber remains fixed, or disable this function altogether so that the clamps behave identically to the previous model of the 80S device. This photo shows the secondary retainer that continues to hold the optical fiber after opening the left clamp. For clarity, the latch is highlighted in blue.

High precision fiber alignment

Fujikura's top-of-the-line splicers always provide the lowest loss when splicing optical fibers. They use high-quality lenses and sensors of the optical system, high-precision motors of the positioning system and intelligent software that regulates the entire process, taking into account the types and condition of the fibers being welded, as well as ambient temperature, humidity, pressure and a number of other parameters.

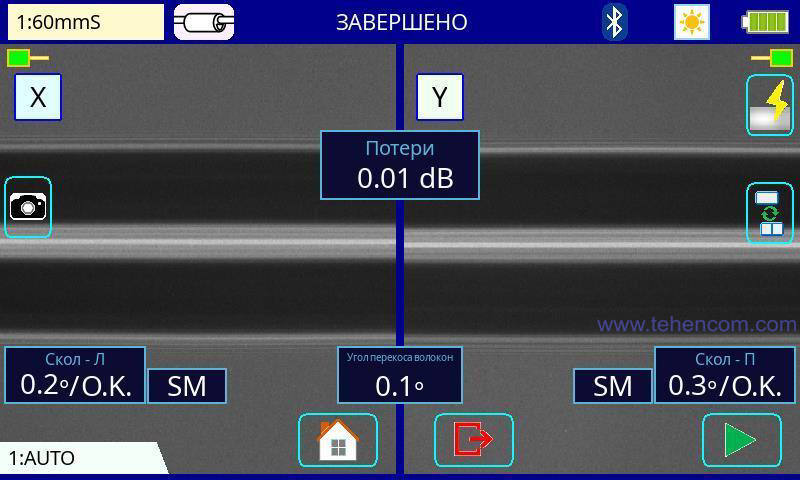

The fiber recognition and alignment system of the 86S is identical to that of its predecessor, the 80S. With its help, it is possible to obtain a detailed image of the fibers, which is necessary for the automatic determination of their types, as well as for accurate information on the core of the fibers. This screenshot clearly shows the high quality of this image.

Wireless connection of the device with the cleaver

One or two automatic cleavers can be connected to the Fujikura 86S via Bluetooth. Fujikura CT50. After the first pairing of the device and the cleaver, the devices remember the settings and their connection is automatically restored each time they are turned on. This function allows the machine to keep statistics on the number of fiber cleaves at each knife working position, and automatically rotate the cleaver knife to the next working position based on the analysis of the cleavage angle and its shape.

This 86S screen shot shows statistics on the number of cleaves completed at each of the sixteen working positions and three working heights of the CT50 cleaver. The current working position of the knife No. 16 (height 1), the working position recommended by the machine No. 1 (height 2). Please note that the average calculated number of chips in each position is 1,250 times, and the real number, performed taking into account the analysis of the quality of the resulting chips, can be either more than 1,250, or less than this value.

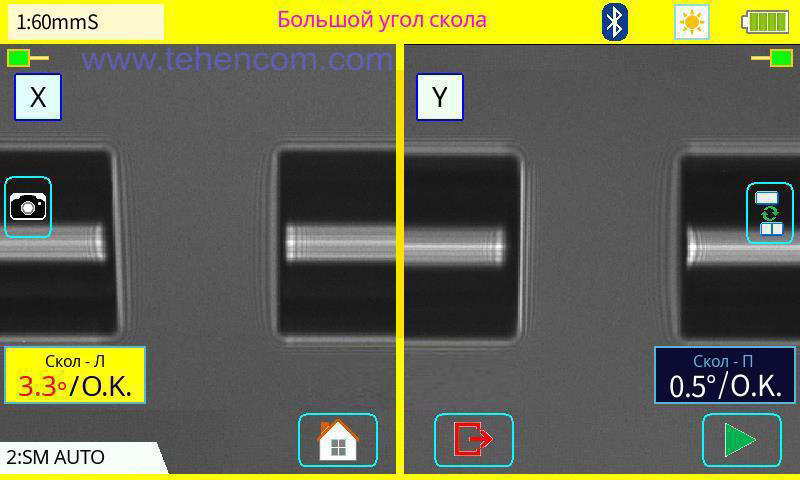

As the knife wears, the cleave angle and shape begin to deteriorate. The machine continuously analyzes both of these indicators, and will turn the cleaver blade to the next working position when necessary. In the screenshot below: the regular appearance of a large chip angle or an uneven chip shape is a sure sign of wear on the current position of the knife, or its contamination, so clean the knife regularly with alcohol.

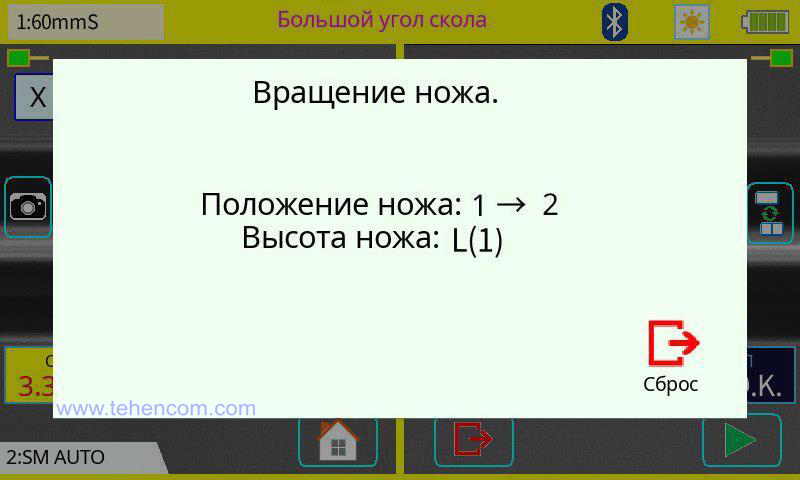

If you want to decide for yourself when to turn the knife, then in the settings of the device you can switch auto-rotate to a simple hint. This is how the information message of the 86S device looks like about turning the knife from the first working position to the second.

Improved case and mounting table

Traditionally, all Fujikura devices are supplied in a convenient and reliable yellow transport case. The case of model 86S is arranged in such a way that it is possible to work with the device simply by opening the top cover of the case. This ensures normal access to the machine and it is possible to place the accessories necessary for welding on the surface of the mounting table. If necessary, you can work by placing the device on the cover of a closed case and fixing it with a special screw.

Another way to organize the welder's workplace is to use a removable mounting table that can be removed from the case and placed on any suitable surface. The appearance of the table with the device attached to it is shown in this photo.

Compared to the previous 80S model, the design of the new mounting table has been completely redesigned. Now it consists of several parts that can be disassembled and assembled in various combinations like a transformer. On the left and right side of the table there are retractable transparent drawers in which you can store the cleaver, stripper, spare battery or any other accessories.

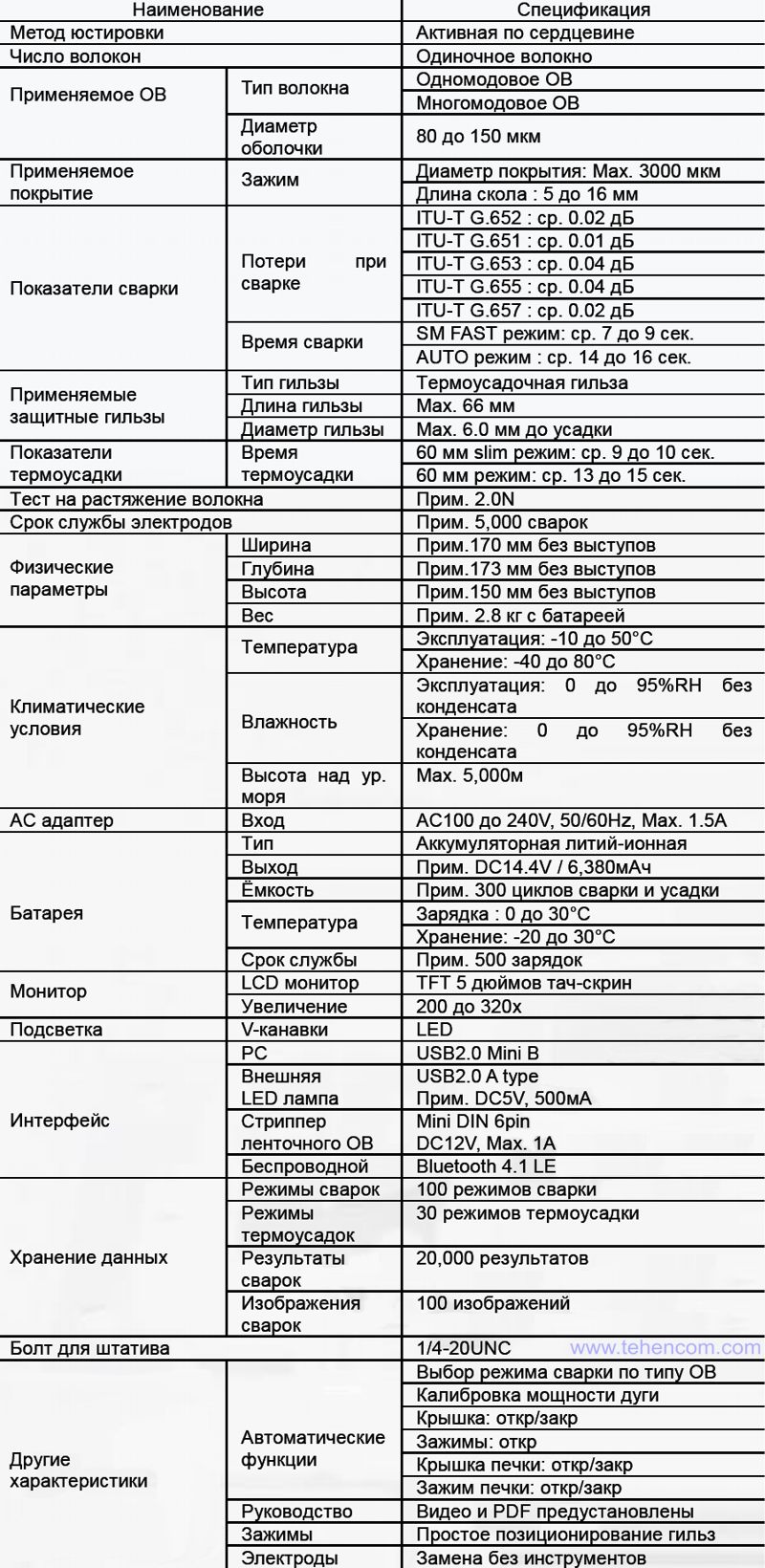

Specifications of Fujikura 86S Universal Fusion Splicer

Here is a list of the main features of the Fujikura 86S universal welding machine. For detailed technical specifications, see below on this page in the section Documentation.

Three options for the delivery of the Fujikura 86S welding machine

The Fujikura 86S optical fiber splicer is offered in three trim levels, which differ in the cleaver model and a set of accessories. The "Kit-A" Plus package is the most complete, it contains the older model of the CT50 cleaver, which is controlled from the device via Bluetooth and can automatically rotate the knife. Also, the kit "Kit-A" Plus includes two pairs of spare electrodes and two additional power cords: from the cigarette lighter and an external battery.

The "Kit-A" Standard package contains the classic CT08 cleaver (without Bluetooth support), one pair of spare electrodes and does not include cigarette lighter or external battery power cords. The third Standard is the simplest and is identical to the "Kit-A" Standard but does not include a cleaver. Below is a detailed list of each of the three kits.

Fujikura 86S Kit-A Plus (the most complete set):

- Fujikura 86S welding machine

- automatic cleaver CT50

- universal fiber optic holders (installed in the device)

- mounting pads SP-03 (1 pair) for installing removable holders of the series Fujikura FH-60 and FH-70

- ELCT2-16B electrodes (1 pair) (installed in the machine)

- Spare ELCT2-16B electrodes (2 pairs)

- BTR-15 rechargeable battery

- Power cord for connecting to car cigarette lighter DCC-20

- Power cord for connecting to an external battery (with alligator clips) DCC-21

- mains adapter ADC-20

- mains power cord ACC-15

- work table for the machine and tools

- bolt for fixing the machine TS-03 (2 pcs.)

- strap for carrying the machine ST -02

- hard case carrying strap ST-03

- USB 2.0 cable (type A - mini B type) USB-01

- alcohol dispenser AP-02

- three-position stripper (0.25 mm, 0.9 mm and 2-3 mm) SS03

- hard case CC-39

- quick reference guide

- computer software (stored inside the machine, available for copying)

- warranty card on 3 years warranty (2 years factory warranty + 1 year from Tehencom)

Fujikura 86S Kit-A Standard (simpler cleaver):

- Fujikura 86S welding machine

- automatic cleaver CT08 with an additional platform for installing fibers

AD-10-M24

- universal fiber optic holders (installed in the device)

- mounting pads SP-03 (1 pair) for installing removable holders of the series Fujikura FH-60 and FH-70

- ELCT2-16B electrodes (1 pair) (installed in the machine)

- Spare ELCT2-16B electrodes (1 pair)

- BTR-15 battery

- AC adapter ADC-20

- AC power cord ACC-15

- working table for the device and instruments

- bolt for fixing the device TS-03 (2 pcs.)

- strap for carrying the device ST-02

- strap for carrying the hard case ST-03

- USB 2.0 cable (type A - type mini B) USB-01

- alcohol dispenser AP-02

- three-position stripper (0.25 mm, 0.9 mm and 2-3 mm) SS03

- hard case CC-39

- quick reference guide

- computer software (stored inside the device, available for copying)

- warranty card for 3 years warranty (2 years factory warranty + 1 year from Tehencom)

Fujikura 86S Standard Kit (without cleaver):

- Fujikura 86S fusion splicer

- universal fiber optic holders (installed in the machine)

- mounting pads SP-03 (1 pair) for installing removable holders of the series

Fujikura FH-60 and FH-70

- ELCT2-16B electrodes (1 pair) (installed in the machine)

- Spare ELCT2-16B electrodes (1 pair)

- BTR-15 battery

- AC adapter ADC-20

- AC power cord ACC-15

- working table for the device and instruments

- bolt for fixing the device TS-03 (2 pcs.)

- strap for carrying the device ST-02

- strap for carrying the hard case ST-03

- USB 2.0 cable (type A - type mini B) USB-01

- alcohol dispenser AP-02

- three-position stripper (0.25 mm, 0.9 mm and 2-3 mm) SS03

- hard case CC-39

- quick reference guide

- computer software (stored inside the device, available for copying)

- warranty card for 3 years warranty (2 years factory warranty + 1 year from Tehencom)

Options and accessories for the Fujikura 86S welding machine

Fujikura 86S machines use universal clamps that allow you to work with fibers in various types of buffer coating. In addition, the 86S devices are equipped as standard with removable mounting pads SP-03, designed to install holders for various types of fiber optic buffer series Fujikura FH-60 and Fujikura FH-70. In a number of situations, especially for beginners, these holders can be more convenient to use, as they allow you to accurately maintain the cleavage length when transferring the fiber from the cleaver to the device. The appearance of the removable holders of the Fujikura FH-60 series is shown in this photo.

- FH-60-250 (for bare fiber 0.25 mm)

- FH-60-900 (for pigtails with 0.9 mm sheath)

- FH-60-DC250 (for 0.25 mm bare fiber with DropCable jacket)

- FH-FC-20 (for patch cords in 2 mm sheath)

- FH-FC-30 (for patch cords in 3 mm sheath)

- FH-60-LT900 (for pigtails in free buffer 0.9 mm)

Of the additional accessories that can be equipped with the Fujikura 86S, you should pay attention to the power supply from a constant voltage source (DC adapter): model DCA-03. This power supply is installed directly into the device instead of the BTR-15 battery. DC voltage can be supplied to the DCA-03 power supply from the standard ADC-20 AC adapter, from the power cord from the DCC-20 car cigarette lighter, or from the power cord from the DCC-21 external battery.

Documentation

This PDF documentation contains the most comprehensive description of the Fujikura 86S fiber splicer features, specifications and operating modes.

Description of Fujikura 86S fiber splicer (in Russian) (9 pages; 2 MB)

Fujikura 86S Brief Information Guide (in Russian) (4 pages; 1 MB)

Fujikura Exclusive Distributor Certificate (1 page; 1 MB)

Fujikura Service Center Certificate (1 page; 1 MB)

And here you can find our tips and other useful information on this topic:

Types of devices according to the method of alignment (alignment) of optical fibers

Effect of electrode wear on welding quality, electrode replacement procedure

What is the difference between Fujikura cleavers? Which model to choose? Questions and answers

How to buy equipment cheaper - discounts, special prices, demo and used devices

To simplify the process of choosing a splicer for fiber optics, you can use our experience and recommendations. We have over 20 years of practical supply experience and can immediately answer many questions about models, options, delivery times, prices and discounts. This will save your time and money. For this it's simple call us or write to us at Email and we will be happy to answer your questions.