What are electronic loads, what are they used for and what are they

Brief introduction

When testing secondary electrical power sources (voltage converters, power supplies, etc.) and some types of primary electrical power sources (batteries, solar panels, etc.), electronic loads are widely used. This material will help to obtain basic information about modern electronic loads, their varieties and the tasks solved with their help.

General information about electronic loads

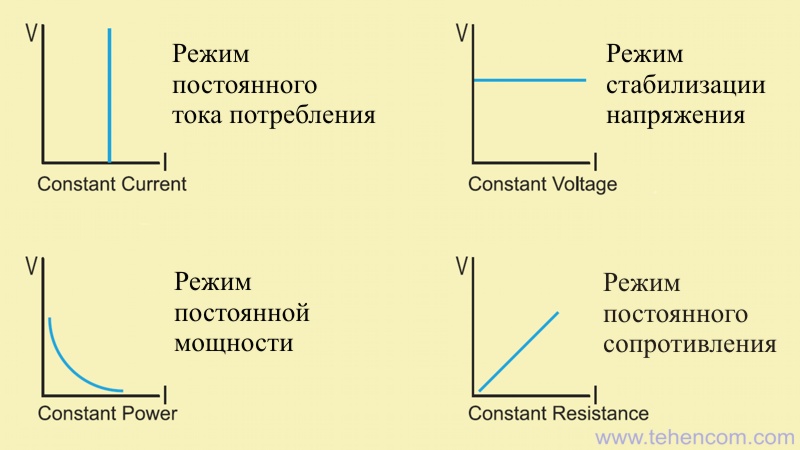

An electronic load is a device designed to simulate various operating modes of a real electrical load. In this case, the electronic load can operate in several consumption modes. The most common are: constant resistance, mode DC consumption, mode constant power and mode voltage stabilization. Also, most models of electronic loads support the mode of changing their state according to a list of user-defined values, which allows you to implement complex test algorithms that best correspond to the operation of the tested devices in real conditions.

What are electronic loads used for?

The main task of electronic loads is testing various power sources: batteries, batteries, power supplies, voltage converters, voltage regulators and stabilizers, solar panels, generators and other similar devices. To perform the test, the electronic load is connected to the power source under test and one or more tests are run. At the same time, the electronic load behaves like a real load: for example, it changes its resistance according to a given algorithm, simulates large starting currents, a short circuit, and other conditions you specify. During the test, the electronic load continuously measures voltage, current and power consumption.

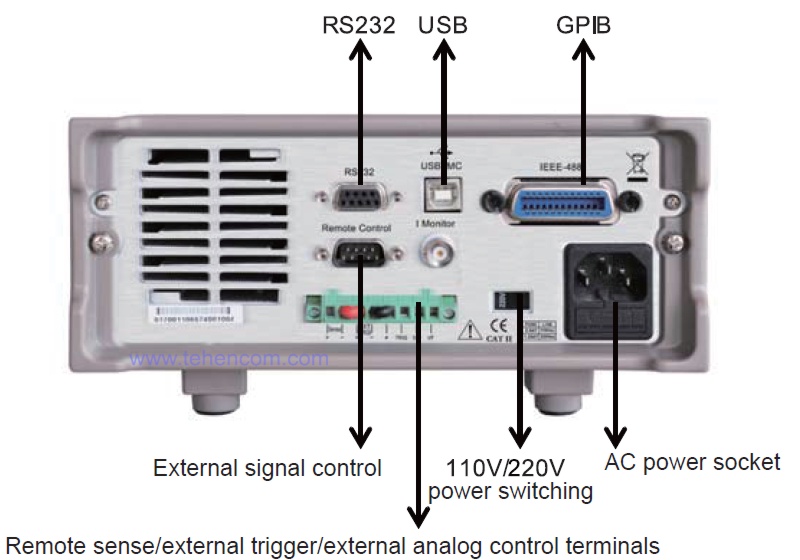

Most electronic loads contain an accurate multimeter that measures the voltage, current, and power drawn by the load. Some models can perform a normalized discharge of batteries and batteries by measuring the actual capacity of the battery in Amp-hours. Many models can also be controlled by a computer, which allows them to be used as part of automated control and measuring systems.

What are electronic loads

Most series of electronic loads are designed for testing DC power supplies (batteries, power supplies, solar panels, etc.), typical examples are: ITECH IT8500+ and series ITECH IT8800. For testing AC power supplies (inverters, uninterruptible power supplies, transformers, etc.), specialized AC/DC electronic AC and DC loads are produced, a typical example: a series ITECH IT8600.

Structurally, serial electronic loads are manufactured in instrument cases. The size and weight of the case is directly related to the maximum power that the load can dissipate. The lowest power models can dissipate around 100W and fit into small, compact cases, such as the 150W IT8211.

More serious models, such as the ITECH IT8818B five-kilowatt load, can be mounted in an industrial rack and weigh 40 kilograms or more.

Models are also produced that can dissipate tens and even hundreds of kilowatts. To see the design options for electronic loads of different power, see the series ITECH IT8800.

Sometimes, to reduce the cost, a rheostat (powerful variable resistor) is used instead of an electronic load. The use of a rheostat when testing power devices is associated with the following limitations:

- no direct current consumption mode;

- no constant power mode;

- lack of voltage stabilization mode;

- the absence of a state change mode according to the list of set values;

- lack of work automation;

- significant inductance of the rheostat;

- the need to use an additional voltmeter and ammeter.

Therefore, instead of outdated testing methods, it is more efficient and ultimately cheaper to use modern test equipment, specially designed for a specific task.

Using a good electronic load can greatly simplify and speed up the process of testing any power supply, as well as make this process safe and efficient.

Video review of electronic loads

In this video, we will look at general information about what electronic loads are, what they are used for and what they are.

Additional information on this topic

We deliberately did not overload this article with the technical details of the electronic load device and a detailed description of their options. All this you can read in detail on the pages individual series of electronic loads.

If you need detailed pricing information or technical advice on choosing the best electronic load for your application, just call us or write to us at E-mail and we will be happy to answer your questions.