Influence of electrode wear on the quality of welding of optical fibers. Procedure for changing electrodes in Fujikura devices

Brief introduction

Modern fiber optic splicers weld optical fibers by melting them with an electric arc that is created between two electrodes. During the operation of the apparatus, the electrodes gradually burn out, which leads to unstable arc parameters and, as a result, to poor-quality welding.

In this article, we will look at how electrode wear affects the quality of optical fiber splicing, pay attention to some important features associated with electrodes and the electric arc of the machine, and also tell you how to properly replace the electrodes in Fujikura splicers.

Varieties of electrodes

Depending on the type of apparatus for which they are intended, the electrodes differ in length, thickness and shape of the mounting thickening. The photo below shows some types of electrodes manufactured by Fujikura. electrodes ELCT2-20A, 20 mm long, are used in most models of Fujikura trunk machines: 80S, 62S, FSM-60, FSM-50 etc. Shortened electrodes ELCT2-12, 12 mm long, are used in miniature models of devices designed for metro networks and access networks: Fujikura 22S, 12S and others. The remaining four models of electrodes, located at the bottom of the photo, are used in obsolete devices: Fujikura FSM-40S, etc.

Real (original) Fujikura electrodes and various imitations and fakes

The original electrodes, which are manufactured in Japan at the Fujikura plant, are made from a special tungsten alloy with careful control of its chemical composition and the geometric dimensions of the electrodes. The length of the electrodes and the shape of the working tip are controlled with an accuracy of 0.01 mm. Accurate electrode sizing is important for arc stability, and the specially selected tungsten alloy composition ensures long life and minimizes tip burnout.

The photographs below show the original Fujikura ELCT2-20A electrodes (left) and one of the counterfeit types (right). The original electrodes are supplied in a sealed package and contain a raised F on the attachment end of each electrode. A pair of original electrodes costs about $60 and provides up to 5000 quality welds. Fake electrodes cost half as much, but, depending on the variety, they are either not able to provide a normal arc at all, or they are cooked, but not of sufficient quality and quickly burn out. Usually such fakes are enough for no more than 2000 mediocre welds.

|

|

Genuine Fujikura ELCT2-20A Electrodes |

Counterfeit for Fujikura ELCT2-20A electrodes |

Arc stability and degradation during electrode wear

When the electrodes are new and the welding parameters are correct, the arc that welds the fibers should be bright, uniform and in the center of the machine screen. If the fibers were not cleaned well enough, then during the operation of the arc, small bright points may appear in the working area of welding. In this case, the arc itself should not abruptly change the brightness or position.

This video shows all the steps of splicing two optical fibers using Fujikura 80S. Pay attention to step 6 of this video, which shows the main arc slowed down by a factor of five.

Even the highest quality and refractory electrodes burn out a little with each arc. Their ends gradually change shape and shorten. Soot accumulates at the very tips. As a result, the distance between the electrodes increases, the device, in order to compensate for the increase, raises the operating voltage of the arc and regulates its other parameters. Due to this constant auto-tuning of the arc parameters, modern firmware of Fujikura welding machines can guarantee up to 5,000 weldings. For today this is a record! After 5,000 splices, the electrodes must be replaced as the arc becomes quite unstable. If you continue to weld without changing the electrodes, then the percentage of bad welds will increase significantly and the machine will often give the error "Unstable arc".

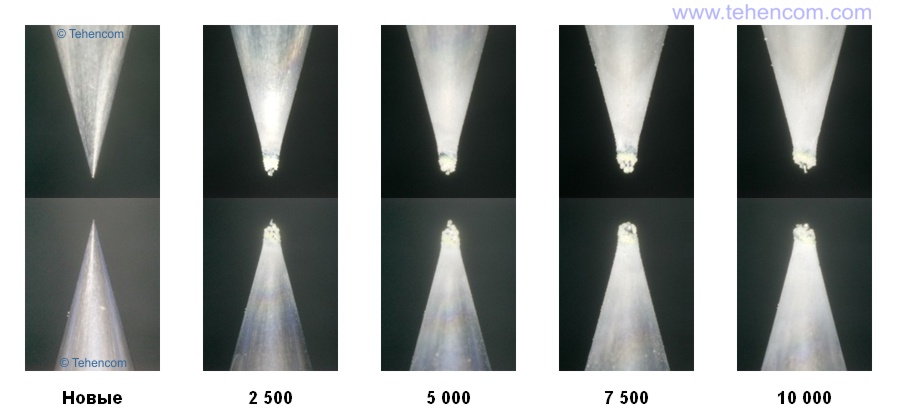

To better demonstrate what happens to the electrodes during operation, this photo shows an enlarged view of the ends of the electrodes after 2,500 splices, 5,000 splices, 7,500 splices, and 10,000 splices.

Electrode Replacement Procedure

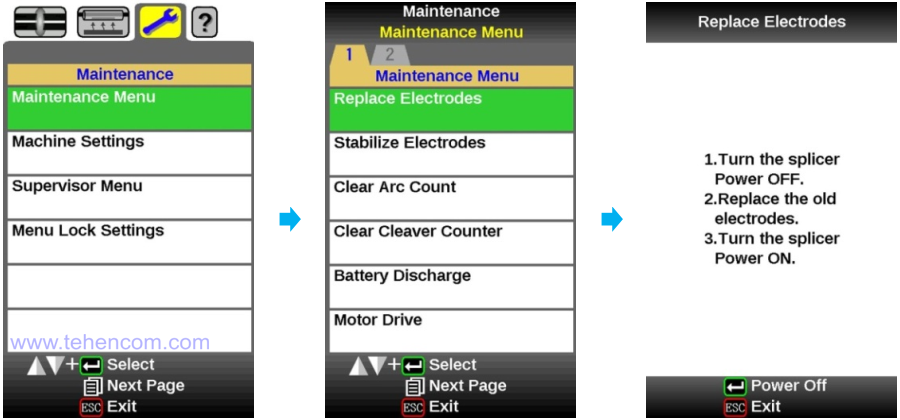

In order to replace the electrodes in the Fujikura device, you need to follow a few simple steps. First you need to go to the menu of the device "Maintenance - Maintenance Menu", then to the submenu "Replacement of electrodes - Replace Electrodes", after that a message will appear so that you turn off the device, replace the electrodes with new ones and then turn on the device.

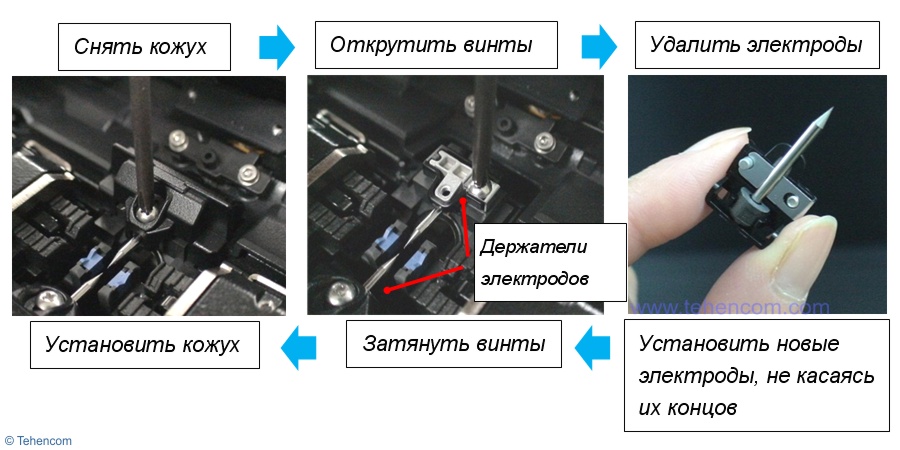

Now you need to turn off the power of the device, unscrew and remove two plastic protective caps from the electrodes. Then unscrew the two screws of the electrode holders. Next, remove the old electrodes and carefully install the new ones, making sure that the ends of the new electrodes do not touch anything during replacement.

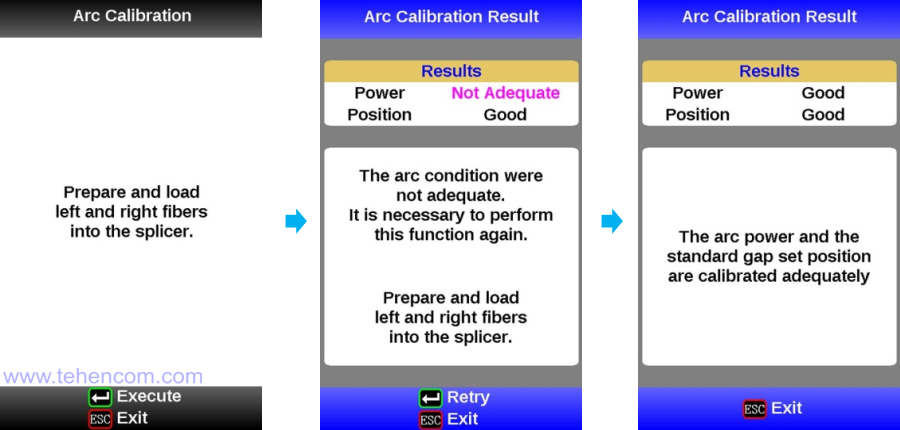

After the old electrodes have been replaced with new ones, it is necessary to turn on the device. A message will appear on the screen asking you to strip, cleave and install two single-mode fibers into the machine. This is necessary so that the machine can perform initial electrode stabilization and arc calibration. During the stabilization process, the device will turn on the arc several dozen times and melt the ends of the fibers without welding them. Analyzing the degree of fusion of the ends of the fibers, the device will automatically correct the parameters of the arc.

If the process of initial stabilization of the electrodes ends with an error in the power or position of the arc, then you simply need to repeat the stabilization procedure. It is necessary to strip, cleave and install another pair of single-mode fibers into the device and press the "Enter" key. After successful stabilization, the device will display a message that the power and position of the arc are "OK". The machine is now ready for another 5000 quality welds.

The corresponding menus of the device are shown in this photo. Please note that all Fujikura devices sold in Ukraine completely Russified.

Summary of information on electrodes and arc

During the operation of the arc, the ends of the electrodes gradually burn out. The machine automatically adjusts the arc parameters to compensate for burnout, but as the number of welds increases, this becomes increasingly difficult.

The use of proprietary Fujikura electrodes and the latest firmware versions of the devices allows you to increase the number of high-quality welds up to 5,000.

After 5,000 splices, the electrodes must be replaced following the procedure outlined above.

Additional information on this topic

For a complete list of Japanese Fujikura fiber fusion splicers, go to the main page welding machines. And to better understand the designs of various types of devices and cleavers, read these materials:

Types of devices according to the method of alignment (alignment) of optical fibers

What is the difference between Fujikura cleavers? Questions and answers

If you need detailed pricing information or technical advice on choosing the best welding machine for your application, just call us or write to us at E-mail and we will be happy to answer your questions.